Above-rafter insulation – determining the right screw

Fastening advice on timber construction

Above-rafter insulation is considered to be energy-efficient roof insulation, because the rafters are correspondingly over-insulated as potential thermal bridges. As the insulation is built on the outside of the roof, the existing interior is retained in this insulation method. It is often used in renovations and new buildings. But what should be considered about above-rafter insulation with regard to screw selection and what errors can be effectively avoided here?

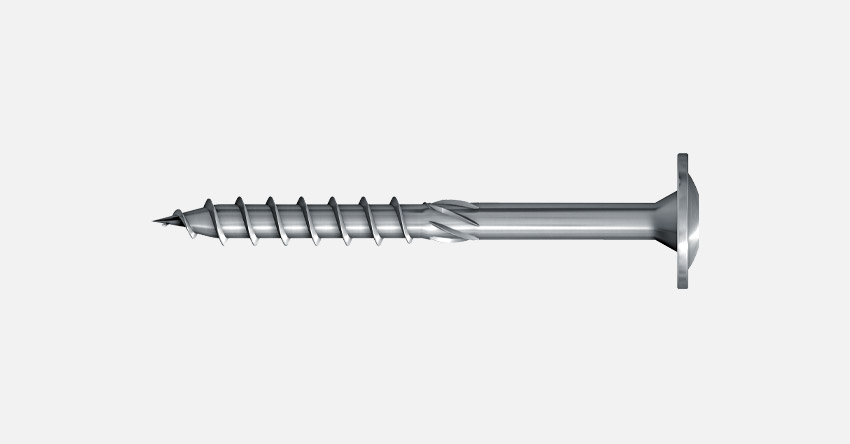

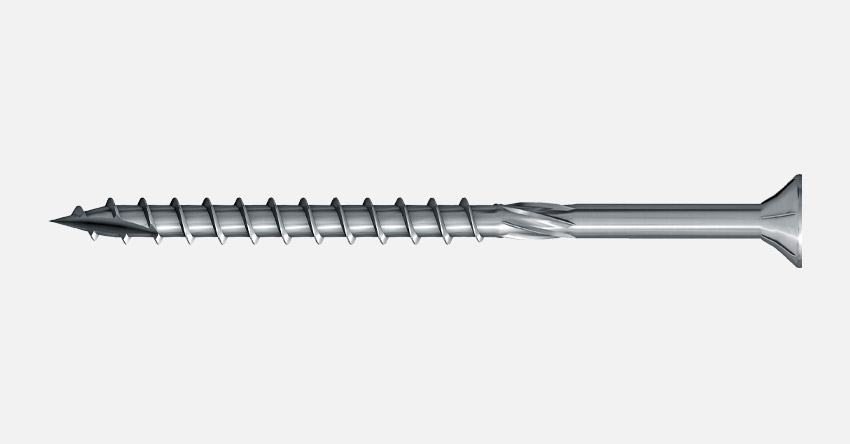

Applications for wood screws in the above-rafter insulation are, for example, the connection of a 30 mm thick support lath to a 40 mm thick counter lath (1) with a T-FAST® JW2-STR-4.0x70/42 wood screw with countersunk head (right), for example in areas with increased wind suction loads, or the attachment of above-rafter insulation (2) with a T-FAST® JW2-STS wood screw with wafer head (left).

Selecting the right screw

For the selection of the suitable fastening method, the insulation is pressure-resistant at 10% compression (≥50 kPa or ≥0.05N/mm²) and low-pressure (<50 kPa or <0.05 N/mm²). According to ETA-18/0812, all pressure-resistant insulation materials may be fitted with a T-FAST® JW2-STR or JW2-STS partial threaded screw with a nominal diameter of 6.0 mm and 8.0 mm by screwing through a counter lath (bmin = 50 mm x hmin = 30 mm). In the market, counter slats with dimensions b=60 mm×h=40 mm are processed. Screw-fastened shear safety screws at an inclination of 65° and suction safety screws at 90° to the roof surface. The thrust and suction securing screws are distributed according to the specifications of a static dimensioning created for each individual construction project.On the graphic, the screws are shown with the angles to the roof surface of 65° (thrust protection) and with an inclination of 90° (suction protection). The first and last anti-thrust screw is always screw-fastened at a distance of 20 cm from the start and end of the counter laths. The distances between them are the result of the dimensioning.

For insulation materials with compressive strength at 10% compression below 80 kPa, it may be useful to work with 6.0 mm JW2-STS or JW2-STR, because an 8.0 mm JW2-STS cannot be fully utilized due to the rather low compressive strength. The version with 8.0 mm JW2-STS is still possible. Lengths of counter laths determine the possible screw distances and influence the number of screws. Short counter lath lengths often lead to a rather increased screw requirement.

Stay away from too short screws

Theoretically, each screw length has a minimum installation depth in the rafters of lef ≥ 4 x nominal diameters may be used. However, partial threaded screws are limited in their load-carrying capacity to being pulled out on the one hand by thread extension and on the other hand by head extension. For example, to achieve the full head penetration capacity of Fax,α,Rk = 6.17 kN of the T-FAST® JW2-STS-8.0, the screw thread must be screwed into the rafter with a depth of approx. lef = 73 mm. A minimum installation depth is, as a practical rule, lef ≥ 60 mm to be reasonable. Lower installation depths can lead to an increased screw requirement. And the greater the installation depth in the rafter, the better the head can be pressed against the counter lath.STR heads (countersunk head, image on the left) are added to the screw length. In the case of screws with STS heads (plate head, picture on the right) resting on them, the screw length is measured to below the head.

The push-in fitting should be fitted at an angle of 65° ±5° inclination, measured between the screw axis and the rafter below the screw. In practice, screw-in aids sawn from a piece of board are useful. Nevertheless, in the course of the work, unplanned angular undershooting may occur, as a result of which the real installation depth is reduced. Longer screws are less prone to errors for this deviation and thus offer the processor an increased design reliability.

As a special service, EJOT offers the preparation of preliminary measurements for its products. Based on your project data, we determine the type and number of fastening means required. For more information on preliminary measurement, please contact your local sales representative.

As a special service, EJOT offers the preparation of preliminary measurements for its products. Based on your project data, we determine the type and number of fastening means required. For more information on preliminary measurement, please contact your local sales representative.