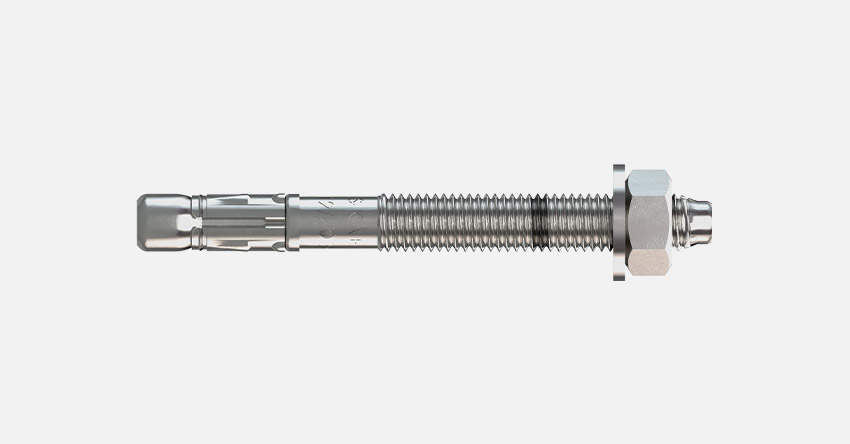

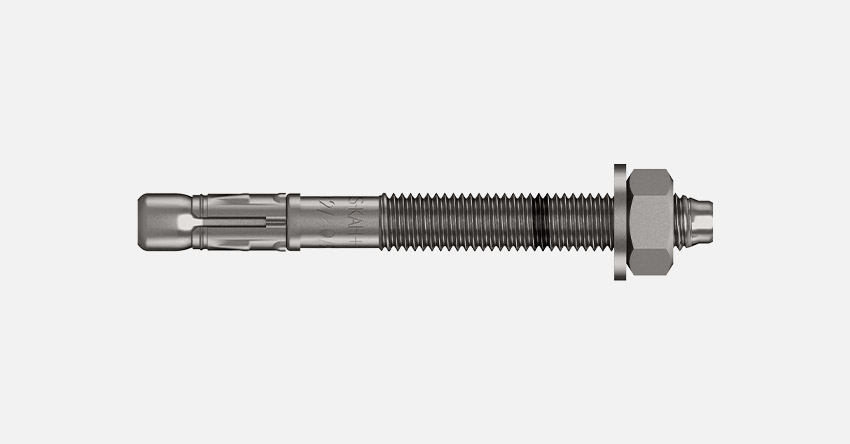

Mounting through bolts

How to avoid installation faults

Through bolts are frequently used as mechanical anchoring solutions for heavy loads in cracked or non-cracked concrete. In our article, we take a look at the special features and functionality of through bolts, and offer valuable tips on how to install them correctly.

What is a through bolt?

A through bolt is a torque-controlled expansion anchor (frictionally engaged) for fastening metal and wooden attachments (medium heavy to heavy loads) to concrete. It meets high requirements towards load bearing capacity and safety. Through bolts are used for fastening heavy and safety-relevant attachments in both indoor and outdoor areas. These include, for example, brackets for signs and lighting, installing awnings, support legs, stairs and railings but also wiring systems, ventilation stacks and cable ducts and, last but not least, anchoring substructures for facades. For outdoor areas, through bolts made of A4 stainless steel or HCR 1.4529 stainless steel are well-suited as they account for special requirements such as highly corrosive environments. But how do through bolts work and what mistakes should you avoid during installation?How do through bolts work?

Through bolts work by driving a steel bolt into the Base material. The correct setting depth can be easily determined by the black marking on the anchor. When installed, this marking must be flush with the concrete surface. When the nut is tightened, a metal shield expands, which in turn clamps the bolt into the substrate. Depending on the respective assessment (ETA), through bolts are suitable for anchoring in cracked and non-cracked concrete.Caution on edges

Due to the expansion forces, the through bolt as a fastening element does have its limits in some applications. This is mainly the case when the fixing points are close to the edge of concrete surfaces. If the concrete does not have enough mass to absorb the expansion forces, the result may be splitting of the substrate material and in the end even complete failure of the fixing point.Three common mistakes when installing through bolts

Mistake no. 1: Fastening point too close to the edge

This example shows a metal handrail that has been fastened to concrete steps with through bolts. The fastening points are at the outer edge of the steps. The occurring expansion forces have damaged the surface of the concrete. In some parts the entire concrete corner has split.The fastening point is too close to the outer edge of the step (left). The corner of the step is broken - this is not going to bear loads (right).

Mistake no. 2: Angled through bolts

It seems that the installer knew that edges are critical, because he tried to prevent splitting by installing the through bolts at an angle. This second installation error is the reason that the through bolt could not be mounted flush with the attachment.The through bolt was installed at an angle and could not be mounted flush with the attachment.

Mistake no. 3: Selection of the wrong attachment point

Out of four possible attachment points, only two were chosen – and were the two least favourable ones, sitting directly on the edge. Here, the expansion forces of the through bolts create a risk that the edge areas of the concrete will split and the fastening will completely or at least partially lose its load-bearing capacity.The fastening points were chosen poorly, too close to the edge area.

Note edge distances, avoid damages

When using through bolts in concrete, the minimum edge distances must be observed and strictly adhered to in order to ensure the comprehensive load-bearing capacity of the fastening. Additionally, drill holes must always be made perpendicularly.As a rule of thumb for the edge distance, at least 6 times the through bolt diameter (6 * d) should be used. Example: through bolt M10 = min. 60 mm edge distance. The currently valid manufacturer assessments (ETA) and the included spacing and edge distances need to be observed as well. The respective European Technical Assessment ETA-18/0219 contains information about the minimum edges distances.

Chemical anchors as an alternative

If it is not possible to observe the minimum distances for structural reasons, the only option is an expansion force-free fastening solution. This usually facilitates smaller edge distances. Suitable for this are chemical anchors. We demonstrate the functionality and comprehensive assembly instructions in our chemical anchors installation video.More interesting information on the topic of anchoring can also be found in our heavy-duty anchor Guidebook.

EJOT® product recommendations for through bolts

The following through bolts are available upon request:

- BA-E-HCR Plus, made of 1.4529 stainless steel for highly-corrosive environments

- BA-F Plus, made of hot-dip galvanised steel for anchoring medium heavy to heavy fastenings