EJOT – much more than "just" screws

Customized components for electromobility

14.07.2023, Market Unit Industry

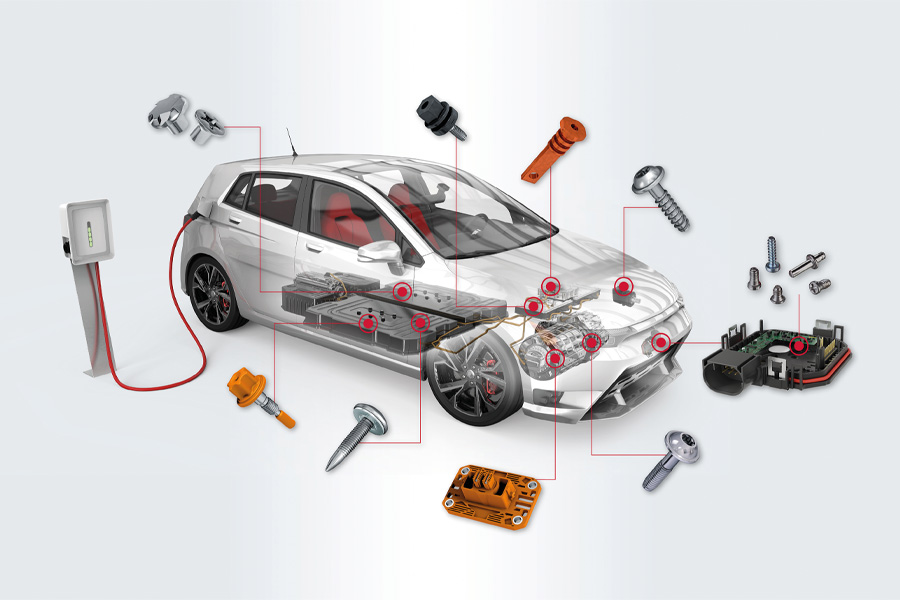

Ever stricter environmental regulations are forcing a radical shift away from "business as usual" toward alternative driving forms, with electromobility leading the way. EJOT, as a fastening technology specialist, can draw on innovative manufacturing technologies in the areas of cold massive forming and plastic injection molding to offer customers tailored solutions in electromobility as well.High-voltage contacting

Products for electromobility often fulfill different functions than "classic" screws. Alternative materials are also used in many applications. For example, EJOT's high-precision components for the high-voltage range of electric vehicles are manufactured from copper instead of steel in a complex, multi-stage cold-forming process. In combination with another EJOT manufacturing specialty, the plastic injection molding, cold massive forming is also the basic technology for special metal-plastic components. These are used, for example, as pole screws for the high voltage contacting of battery modules or as spacers for the electrical decoupling of printed circuit boards in an on-board charger.

Battery systems

With regard to batteries, the focus at EJOT is again on "fastening". Wherever maximum assembly reliability and performance are required, the flow drill FDS® screw, which is already used for the body-in-white construction, can fully demonstrate its advantages. Equipped with a special sealing function for this application, it ensures that the battery housing is securely fastened to the cover. EJOWELD® friction welding, also known from body-in-white construction, comes into play when aluminum components have to be fixed to the battery frame. And if the battery box is made of plastic instead of metal, EVO PT® screws enable process-safe direct fastening of the cover to the battery frame. During the design stage, they also offer FEM-based component analysis and the digital EVO CALC® calculation service.

TOBI® – the high-performance screw drive concept

The TOBI® Drive System is a brand new drive concept. Thanks to the special design between drive and bit, three important requirements can be combined: The axial alignment of the system when inserting the bit into the screw head drive simplifies handling even in areas that are difficult to access. A contact surface between bit and drive that is up to 10 times larger ensures lower surface pressure and thus less wear on the tools. And finally, the large concave and small convex radii inside the drive as well as a taper to the upper edge of the bit lead to a slight clamping effect of the screw so that it cannot fall out of the bit. This enables safe working in all positions, such as overhead assembly or when fastening components or parts in hard-to-reach areas – even in automated fastening processes.

Furthermore, the self-retaining effect of the TOBI® Drive System means that the vacuum technology previously used in assembly for the intake of the screw in the mouthpiece can be omitted. The drive system also holds screws made of non-magnetic materials securely in all positions. This leads to significant cost and time savings as well as a reduction of the CO2 footprint in production.

Learn more: www.tobidrive.com

EJOT at the FAKUMA 2023:

Friedrichshafen (Germany), 17 to 21 October 2023Hall B3, stand B3-3111

Your contact

Andreas Blecher

Team Manager Marketing

Broad EJOT product range for applications in electromobility.

Picture: EJOT

Picture: EJOT

TOBI® – the high-performance screw drive concept.

Picture: EJOT

Picture: EJOT