No more defects in the RVF

New fastening system to avoid broken panels and visual imperfections

29.01.2025, Market Unit Construction

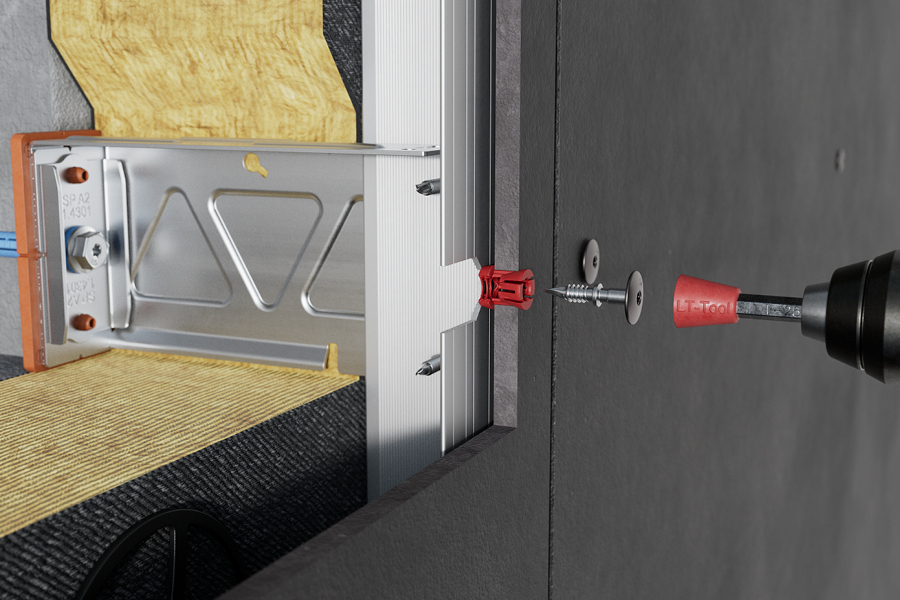

Two serious and regularly occurring problems with rear-ventilated facades using fibre cement panels could soon be a thing of the past: no more unsightly light marks on the facade panel in the area of the substructure and no more broken panels at the fixing points. The new, patented LT-TD system from EJOT fundamentally eliminates these weak points.

The LT-TD system consists of new centring sleeves for sliding and fixed points, as well as a selection of bimetal and stainless steel screws for fastening the facade panel to the substructure made of steel, aluminium or wood. The design of the centring sleeve and the special design of the associated self-drilling screw ensure that the screw is positioned straight and absolutely centred, thus guaranteeing uniform clamping lengths across the entire facade. A special collar at the upper edge of the screw's clamping area guarantees a precise setting point and thus a defined clamping length and a 90° angle to the substructure. Temperature-related expansions of the various materials used on the facade are compensated by the interplay of optimally designed fixed and sliding points. Fractures or deformations of the facade cladding are avoided.

At the same time, there are special snap-fits in the lower part of the centring sleeve. These ensure that the plate is held securely in place while also creating a 3 mm air gap between the cladding and the substructure. The advantage is that the plates are evenly ventilated in the area of the the profiles, thermal bridges are avoided and the facade dries evenly in damp weather conditions. This means that the visually disturbing light marks around the profiles will be avoided in the future.

The new LT-TD system is also well thought out in terms of sustainability. Unlike rivets, screwed facade panels can be quickly and easily removed and simply replaced in the event of renovation. This saves time and costs. In addition, no special tools are required. A glance at the construction site reveals another major advantage of the centring sleeves used in the LT-TD system: the sleeves used in the LT system have a permanent functional purpose and remain in the drill hole. The assembly is thus completely residue-free.

Your contact

Katrin Strübe

Content Marketing Manager

With the LT-TD system, EJOT is presenting a new, patented system for the visible fastening of facade panels.

Picture: EJOT

Picture: EJOT

About EJOT®

The EJOT Construction Division caters to selected segments of the building in-dustry. This includes professional applications on building facades and installa-tion solutions for technical facilities inside the building. The main products are drilling and sealing screws, anchors, mounting elements and profiles for External Thermal Insulation Composite Systems (ETICS), chemical and mechanical an-chors as well as fasteners for flat roofs and solar applications.

Whether it is the construction of the highest tower, the most spectacular nuclear reactor protective cover or the southernmost polar station in the world – EJOT customers rely on many years of experience in the building industry.

EJOT – that is more than 4,700 employees in 51 locations, more than 24,000 products and one hundred years of company history.