Anchoring with through bolts and injection systems

Guide for rainscreen facades – Part 5

Our guidebook on rainscreen facades has already discussed the structure and the advantages of a rainscreen facade, the basics of anchoring, the characteristics and special features of single or multiple fastening of non-load-bearing systems, as well as the correct selection and installation of plastic facade anchors.

The current part of our guidebook deals with the use of through bolts and presents the possibility of anchoring by means of an injection system.

The current part of our guidebook deals with the use of through bolts and presents the possibility of anchoring by means of an injection system.

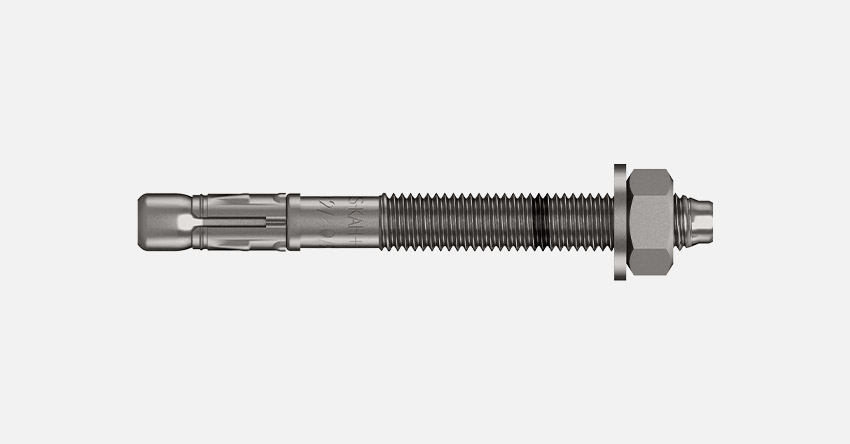

Correctly inserting through bolts

Through bolts belong to the torque-controlled anchors. They are activated by applying a predetermined torque. Too little torque can result in the anchor slipping and the fastened component sagging. Excessive torque can cause the substrate to split or the anchor to fracture. It is therefore particularly important to activate the anchors with the predetermined torque using a torque wrench.Through bolts achieve their load-bearing capacity even in cracked concrete or in the case of seismic requirements through their aggressive expansion and the ability to expand afterwards. For this reason, certain points must be taken into account when using through bolts. The expansion pressure on the concrete is so high that edge distances and anchoring depths must be maintained. Otherwise, the anchor will blow up the concrete or only provide greatly reduced load-bearing capacities. Pre-dimensioning programs such as EJOT ANCHOR FIX are therefore recommended for the design of anchors. It contains all specifications regarding the installation conditions of the anchor and evaluates the load on the anchor in real time.

Anchoring with injection systems

Injection systems are used in particular for rainscreen facades, if another anchor no longer achieves the required loads. They allow maximum loads even with thin-walled perforated bricks.EJOT currently offers two different types of injection mortar for the secure embedment in masonry and concrete. The Multifix USF is a mortar that can be used universally. It can be embedded in concrete, in countless solid and perforated bricks, as well as in aerated concrete. To fulfil as many applications as possible, there are anchor rods of diverse diameters and lengths available in the portfolio. In addition there is a fitting mesh sleeve for each anchor rod diameter. The mesh sleeve prevents the mortar from disappearing uncontrolled in the chambers of the stone when the mortar is injected into a perforated stone. EJOT offers all anchor rods with zinc-plating and in stainless steel, with fitting nuts and washers. Maximum flexibility is guaranteed by the 1000 mm long anchor rods, which can be abridged individually by the contractor as desired.

The next part of our guidebook on rainscreen facades will deal with the selection of the right material for the substructure of the rainscreen facade as well as the formation of fixed and sliding points. In addition, the CROSSFIX® substructure system from EJOT is presented, which enables a particularly flexible and thermal bridge reduced assembly of rainscreen facades.

The next part of our guidebook on rainscreen facades will deal with the selection of the right material for the substructure of the rainscreen facade as well as the formation of fixed and sliding points. In addition, the CROSSFIX® substructure system from EJOT is presented, which enables a particularly flexible and thermal bridge reduced assembly of rainscreen facades.